Opening the Benefits of Membrane Layer Switch Modern Technology for Your Organization

In the realm of item development, the integration of membrane button technology supplies an engaging advantage for organizations intending to improve individual interfaces. Identified by its resilience, streamlined design, and customizable functions, this modern technology adjusts perfectly throughout varied industries, from medical devices to consumer electronic devices. By exploring exactly how these switches can be customized to meet specific functional needs, firms can dramatically fine-tune product functionality and aesthetic allure, leading the way for ingenious applications that resonate with contemporary customer assumptions.

Understanding Membrane Switch Over Modern Technology: Features and Mechanisms

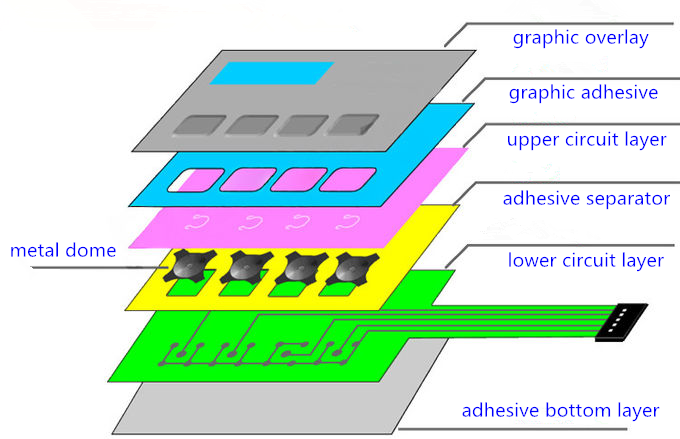

Membrane button technology integrates interface with digital gadgets through an adaptable, pressure-sensitive wiring. This technology makes use of layers of thin movies including conductive inks to form the circuits and switches. Under the surface, these layers include a spacer, a non-tactile or tactile overlay, and a conductive trace that reacts to touch. When a customer presses the overlay, it reaches the underlying circuit, closing the switch and sending out a signal to the tool's control system.

The versatility of membrane layer switches is improved by their longevity and low account. They are immune to dirt, dampness, and extreme chemicals, making them perfect for a range of settings. In addition, these buttons can be personalized with various appearances, colors, and visuals overlays to fit particular aesthetic and functional requirements. The technology likewise sustains backlit keys and clear windows for LED displays, improving individual interaction and ease of access.

Practical Applications of Membrane Switches Over in Various Industries

Provided their convenience and durability, membrane buttons locate comprehensive applications throughout various sectors - Membrane Switch. In the healthcare field, they are vital for medical devices such as ventilators and infusion pumps, where integrity and sanitation are paramount. The lightweight and easy-to-clean nature of membrane layer buttons also make them suitable for use in portable clinical screening sets

In industrial settings, these buttons are applied in control panels for manufacturing equipment. Their capability to endure harsh atmospheres, like exposure to chemicals and severe temperature levels, ensures long-term reliability popular problems.

The consumer electronic devices sector gain from membrane buttons in products like microwave ovens and push-button controls (Membrane Switch). Their thin profile and adaptable layout permit for streamlined, modern-day appliances that are user-friendly and visually pleasing

Strategies for Integrating Membrane Switch Over Solutions Into Your Products

Following, collaboration with experienced membrane layer switch suppliers is vital. These professionals can provide assistance on the customization of design elements such as responsive feedback, backlighting, and graphic overlays, making the switches a lot more instinctive and lined up with the product's aesthetic.

Moreover, prototyping is an essential step. Evaluating use this link various designs in real-world situations assists refine the functional designs and operational performance prior to completing the item. By following these calculated actions, firms can effortlessly incorporate membrane button options, possibly resulting in improved item usability and customer contentment.

Verdict

In conclusion, useful link adopting membrane layer switch modern technology supplies substantial advantages for businesses looking for to enhance product capability and style. These switches provide adjustable, durable remedies that accommodate diverse sector needs, from medical care to consumer electronics. By integrating features like tactile responses and backlighting, business can boost individual interaction and fulfillment, thereby driving development and keeping significance in affordable markets. Welcoming this modern technology is a critical action in the direction of weblink improving product offerings and increasing organization growth.

In the world of product development, the assimilation of membrane layer switch modern technology uses an engaging advantage for organizations intending to improve individual interfaces.Membrane switch innovation integrates user interfaces with electronic devices via an adaptable, pressure-sensitive wiring. To properly incorporate membrane layer switch technology, organizations must initially carry out a thorough evaluation of their items' user interfaces to recognize capabilities that can be boosted by the responsive reaction and sturdiness of membrane buttons. By following these strategic steps, business can perfectly integrate membrane layer button options, potentially leading to boosted item usability and consumer fulfillment.

In conclusion, taking on membrane layer button innovation uses substantial advantages for services seeking to enhance product capability and style.